Running a vending operation isn’t just about keeping machines stocked — it’s about doing it efficiently. Every unnecessary kilometer, every extra stop, and every van packed “just in case” quietly eats into your profits.

The truth is, route planning is one of the biggest hidden costs in any vending business — but also one of the easiest to optimize. With real-time machine data, operators can make smarter decisions, reduce wasted time, and increase profitability without adding more staff or vehicles.

Here are five proven ways to cut route planning costs using live machine data.

1. Visit only the machines that actually need attention

Most vending routes still include machines that don’t need to be visited. Without live visibility into stock levels, sales, or cash collection, operators rely on fixed routines or “gut feeling.”

It’s a familiar story: refillers drive the same routes they’ve done for years, confident they “know every machine.” But customer habits change. A busy office can quiet down, or an event can suddenly spike demand in another area. One day, a machine runs empty because it’s last on the list — while another is refilled unnecessarily even though it’s still full.

Each avoidable trip means wasted fuel, labour, and time. Multiply that by a fleet of 100 machines, and the losses quickly become substantial.

Real data shows: Operators using live telemetry to plan routes cut unnecessary visits by up to 65%, saving thousands of euros annually in fuel and labour costs — while improving machine uptime and customer satisfaction.

Costs reduced: fuel, labour hours, unproductive trips

2. Pack smart, not more

Guesswork doesn’t end with route planning — it continues in the warehouse. When refillers don’t know what each machine needs, they overpack. Vans become moving storerooms, and products sit idle for days or even weeks.

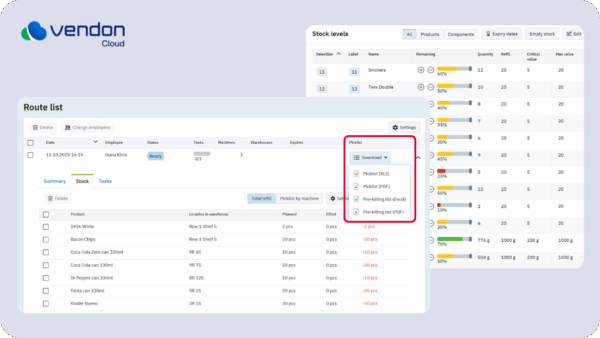

Pre-kitting based on real-time stock data changes that completely. Before leaving, refillers know exactly what to take, for which machines, and where to find those items in the warehouse. No searching, no overpacking, no expired stock.

Real data shows: Operators who use data-driven pre-kitting cut refill times by up to 50% and reduce product waste by up to 30%. Less weight in vans also means lower fuel consumption and fewer damaged goods.

Costs reduced: product waste, warehouse inefficiency, time spent loading and unloading

3. Combine refill, maintenance, and cash collection in one visit

Every visit carries a cost — and handling tasks separately multiplies it fast. Without integrated data, refillers might service a machine one day, technicians visit it the next, and the cash collection team shows up a week later.

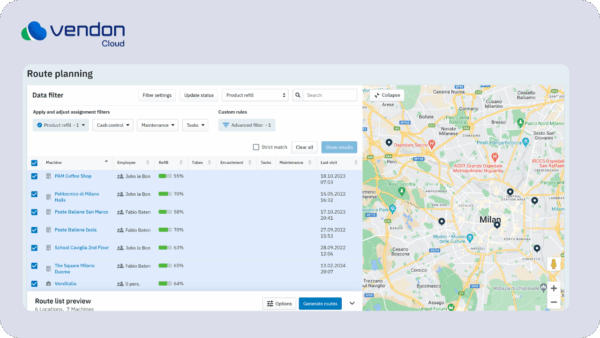

Live machine data brings these tasks together. With a single dashboard showing stock levels, technical alerts, and cash thresholds, operators can plan one efficient visit that covers everything.

Example: If a machine needs restocking, a coin tube refill, and a bill validator cleaning, those tasks can be assigned to the same employee — provided they have the right tools and permissions.

Real data shows: Operators who consolidate tasks through Vendon Cloud Route Planning reduce total visits per week by 35–45%, significantly cutting vehicle use and technician overtime.

Costs reduced: travel, service hours, downtime, duplicate trips

4. Adapt routes dynamically

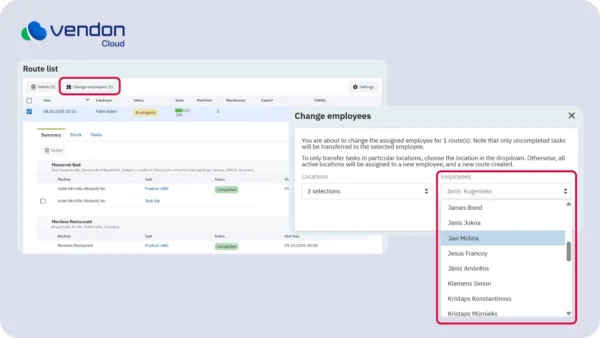

Fixed routes may feel safe, but they’re rarely efficient. Real-world operations change daily — someone calls in sick, traffic slows a driver, or a high-turnover location suddenly needs urgent service. Without flexibility, one disruption can throw off the entire day.

Dynamic route planning powered by live data helps you adapt instantly. Managers can see each employee’s progress in real time, reassign machines to another route, and balance workloads with a few clicks.

Real data shows: With flexible routing, operators can manage up to 30% more machines using the same staff — simply by eliminating wasted travel and optimizing who goes where.

Costs reduced: overtime, idle hours, inefficiency from fixed routes

5. Track and improve continuously

Route optimization isn’t something you do once — it’s a continuous process. The best operators treat it like a performance loop: measure, learn, adjust.

Live data provides a full picture of operational efficiency — how long each refill takes, how many machines were visited unnecessarily, and how stock accuracy compares to plan. Over time, this helps identify patterns and fine-tune schedules.

Real data shows: Operators who continuously track and adjust routes achieve up to 55% savings in routing-related costs within the first year, mainly from reduced mileage, better workload balance, and fewer service interruptions.

Costs reduced: recurring inefficiencies, fuel, unplanned maintenance, and downtime

The bottom line – cutting costs with confidence

Cutting route planning costs isn’t about doing more — it’s about doing smarter.

When decisions are based on live machine data rather than routine, every trip becomes purposeful. You visit the right machines, bring exactly what’s needed, and eliminate waste at every step — from warehouse to customer.